When considering materials for running natural gas lines, safety, durability, and code compliance are at the forefront of every professional’s checklist. One commonly asked question among homeowners and DIY enthusiasts is whether PVC (polyvinyl chloride) can be used for natural gas lines. While PVC is a versatile and widely used plastic material in many types of plumbing systems, it is not approved for conveying natural gas in any residential, commercial, or industrial application. The primary reason lies in the inherent safety risks associated with using PVC for gas. PVC is not designed to withstand the pressures, potential chemical interactions, or temperature fluctuations involved in gas transport. Unlike water lines, which operate under relatively low pressure and do not pose an ignition risk, natural gas lines require materials that are both chemically resistant to gas corrosion and capable of maintaining structural integrity under a range of environmental conditions. PVC is prone to becoming brittle over time, especially in colder climates, and can crack under stress or impact—posing a significant safety hazard if used to transport flammable gases like methane or propane. Furthermore, PVC joints and fittings are often solvent-welded, which may not be gas-tight or suitable for high-pressure gas systems. This creates the potential for leaks that could lead to fire, explosion, or carbon monoxide poisoning.

Regulatory Codes and Legal Restrictions

The use of specific materials for gas piping is tightly regulated by local, state, and national building codes. In the United States, both the International Fuel Gas Code (IFGC) and the National Fuel Gas Code (NFPA 54) explicitly prohibit the use of PVC for natural gas applications. These regulations exist to ensure that materials used in gas lines meet stringent performance standards, including pressure resistance, joint security, and long-term durability. Instead of PVC, commonly approved materials include black steel pipe, corrugated stainless steel tubing (CSST), and polyethylene (PE) pipe—each offering specific benefits depending on the installation context. PE pipe, for example, is widely used in underground gas distribution systems thanks to its flexibility, corrosion resistance, and ability to be fused using heat, creating seamless connections. However, it’s worth noting that PE pipe is only approved for outdoor underground use and must not be used indoors or above ground unless encased. These legal frameworks are strictly enforced, and violations can result in fines, denied permits, or worse—devastating safety incidents. That’s why professional contractors such as GGNC Construction Services always adhere to up-to-date code requirements and industry best practices when installing gas lines, ensuring safe operation for years to come.

Material Alternatives and Professional Recommendations

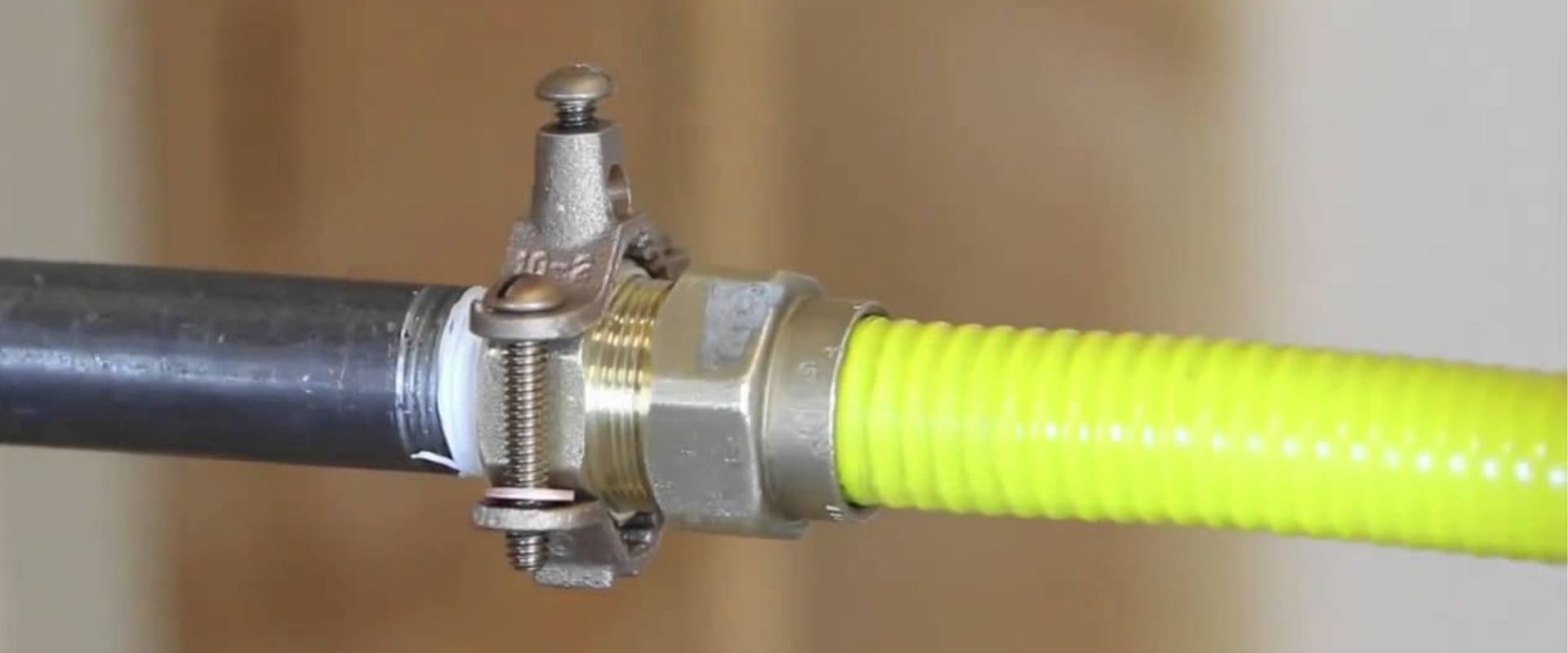

When planning a gas line installation, it’s essential to choose a material suited to the specific environment and use case. Black iron pipe has been a longstanding standard for indoor natural gas lines due to its strength and reliability. It can withstand high pressures and is commonly used in both residential and commercial buildings. However, black iron pipe is heavy, labor-intensive to install, and prone to corrosion over time, particularly in moist environments. CSST has gained popularity as a modern alternative for indoor use. It is lightweight, flexible, and faster to install than rigid steel pipe, making it ideal for complex routing through walls, ceilings, or attics. However, it must be properly bonded and grounded to prevent damage from electrical arcing, which has been linked to some fire hazards in the past. For underground applications, PE piping is often preferred due to its resistance to corrosion and ease of installation, but again, it is not suitable for indoor runs. Each material has its pros and cons, and only trained professionals can determine the best solution based on building layout, gas type, pressure requirements, and code mandates.

Why DIY Isn’t the Best Route

Installing or modifying a gas line is not a typical DIY project. Aside from the legal ramifications of non-compliance, gas lines carry inherent risks that require licensed expertise to mitigate. Even a small leak can have catastrophic consequences. Improper material selection, joint connections, or pressure testing can lead to fire, explosion, or poisoning. Professional gas installers not only bring the tools and knowledge required to complete the job safely—they also know how to acquire necessary permits, follow inspection protocols, and coordinate with utility companies when needed. Additionally, professional involvement ensures that homeowners won’t run into insurance issues later, as many policies exclude coverage for damages caused by unauthorized or non-compliant work.

Conclusion: Safety Comes First—Always

PVC may be a reliable and cost-effective choice for water supply lines and drainage, but it is unequivocally unsuitable for natural gas piping. Its material limitations, lack of pressure tolerance, and incompatibility with gas code requirements make it a poor and dangerous substitute. Instead, safer alternatives such as black steel, CSST, and PE piping are available—each with clear guidelines for proper usage. By consulting with licensed professionals like GGNC Construction Services and following all applicable codes, homeowners and contractors can ensure a safe, efficient, and compliant gas line installation. Ultimately, when it comes to transporting flammable gases, cutting corners or making uninformed material choices is never worth the risk.